Tray Sealing/Vacuum Skin Packaging (VSP) Equipment

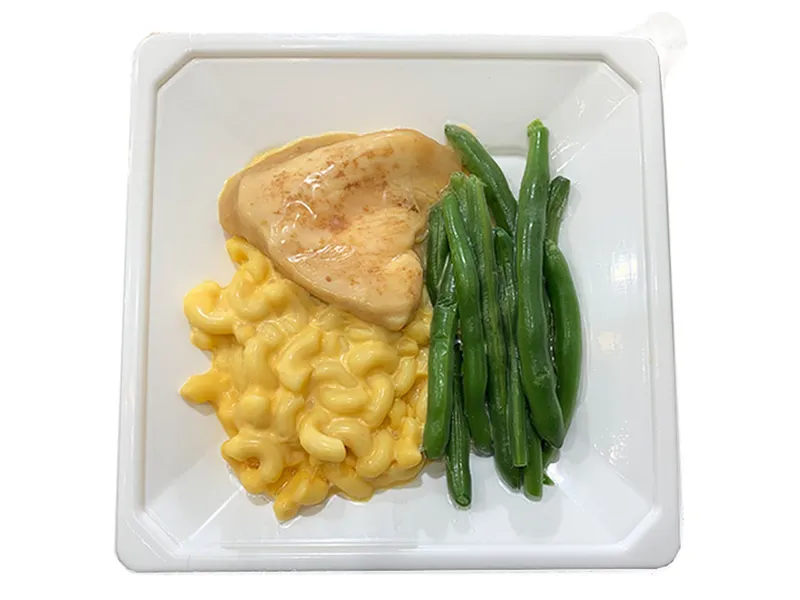

Ossid offers an extensive line of tray sealing equipment, perfect for MAP and VSP packaging applications.

ReeTray 30 Tray Sealer

The ReeTray 30 is a semi-automatic tray sealing machine designed to meet the production needs of small to medium size processors. It is also ideal for large processors looking to run test batches prior to a product launch or larger machine purchase.

The ReeTray 30 is simple to set up, and its functionality makes this entry level machine a great first step into packaging machinery. It can produce ambient, modified atmosphere packaging (MAP) and vacuum skin pack (VSP). Featuring rugged stainless steel construction, manual or semi-automatic drawer feed and interchangeable tooling that delivers fast changeover between tray sizes.

ReeEco Tray Sealer

The ReeEco Automatic Tray Sealer is the perfect intersection between high performance, low power consumption, and a compact footprint.

The standard infeed conveyor allows for up to 3 loading positions, easy tooling changeover, and a user-friendly control panel that gives this model a high level of functionality.

The ReeEco does not require compressed air. All of ReePack’s automatic tray sealer machines operate using only electricity, excluding any pneumatic support.

ReeMatic Series MAP Tray Sealers

The ReeMatic Series MAP tray sealers are designed to meet the needs of medium to high-level processors, offering reliable and efficient solutions for ambient, Modified Atmosphere Packaging (MAP), and Vacuum Skin Pack (VSP) packaging.

Key Features:

ReeMatic 150: Multi-lane tray loading conveyor customizable from 1 to 6 tracks.

ReeMatic 250: Multi-lane tray loading conveyor customizable from 1 to 4 tracks.

Tray Transport System: Pusher rods guide trays step-by-step along the line to the defined die-set position for precise sealing.

Efficient Packaging Output: Driven motors and electrical die-set vertical motion ensure fast and efficient packaging operations.

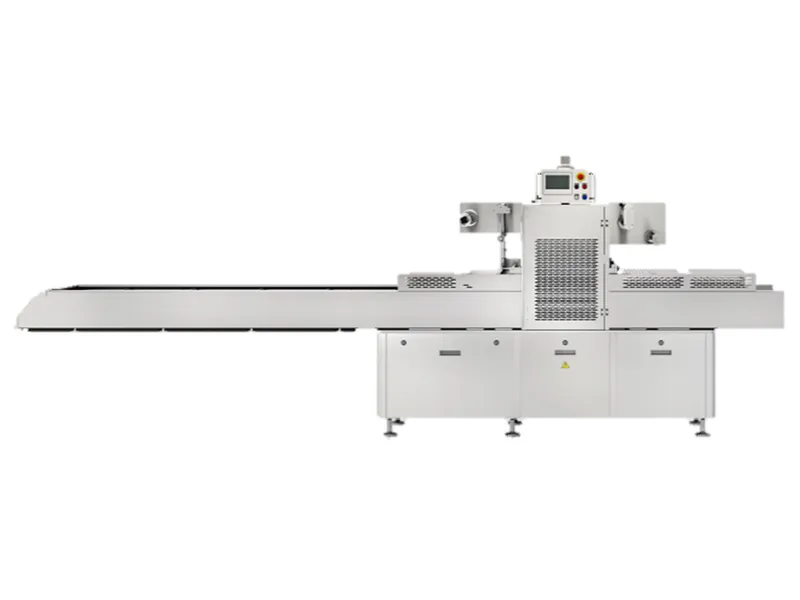

ReeMaster Series Tray Sealers

The ReeMaster Series are fully automatic tray sealing systems designed to meet the production needs of medium to high size processors. Machines are available in a wide range of sizes depending on output needs and tray formatting. Speeds range from 8-45 cycles per minute, depending on tray and film materials, tray size, product, package format, and general machine configuration.

These machines are a robust, affordable solution designed for sealing/lidding trays, cups, and rounds and/or vacuum skin pack applications.

The in-line design allows 360° access to all machine components and tooling, allowing for easy maintenance and cleaning. Stainless steel washdown construction provides the highest level of sanitization. These machines feature a compact frame and small footprint.

Contact US

For general information or to set up an appointment please complete the form below or give us a call.

GENERAL INQUIRIES

Sales (905) 847 0122 EXT 1

Accounting (905) 847 0122 EXT 4